Aluminum Fabrication Services: Built for Performance

Delivering expertly crafted aluminum parts engineered to meet your highest standards for strength, durability, and quality.

01

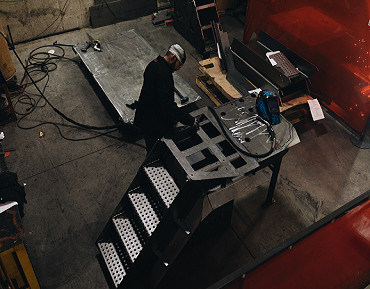

Advanced Aluminum Fabrication Crafted for Your Success

At Sintel, advanced aluminum fabrication means combining decades of experience with modern engineering and machinery to produce parts that meet strict performance and quality criteria. Our integrated approach focuses on quality, reliability, and manufacturability, enabling us to deliver trustworthy aluminum products that support your operational goals. We transform your requirements into efficient, high-quality solutions that drive your success.

02

Why Choose Sintel for Aluminum Fabrication?

01

Material Expertise

Skilled in working with aluminum, as well as carbon steel, stainless steel, and specialty alloys, we deliver parts optimized for durability and corrosion resistance.

02

Advanced Fabrication Processes

By utilizing precise cutting, forming, welding (MIG, TIG, arc), and finishing techniques, such as powder coating, we ensure high-quality fabrication results.

03

Complete Project Management

We manage every phase of your project, from concept to final delivery, ensuring parts meet your specifications and industry standards.

04

Industry-Specific Solutions

Our fabrications meet the rigorous requirements of various sectors, including manufacturing, power generation, heavy equipment, and others.

05

Quality Assurance

Each project undergoes thorough inspections and quality control to guarantee safety, performance, and longevity.

06

Flexible Collaboration

Whether working from your drawings or developing new solutions, we align our engineering and manufacturing expertise with your goals.

03

Our Aluminum Fabrication Capabilities

Sheet Metal Fabrication

Expert laser cutting, bending, and shaping transform aluminum sheets into complex, durable parts with consistent accuracy.

Welding

Skilled technicians perform manual and automated welding, including MIG and TIG, to create strong, flawless joints for lasting assembly. The aluminum weld area is a separate, environmentally controlled area to meet all safety and quality standards.

Forming & Bending

Advanced press brakes and tooling ensure precise shaping of aluminum components, tailored to your exact design requirements.

Finishing Services

Protective and decorative finishes, such as powder coating, enhance both durability and aesthetics, extending part life and appeal.

Prototype to Full Production

From initial prototypes to production runs, we maintain strict quality control and efficiency throughout every stage of the process.

04

Industries We Serve

Our services support manufacturers across industries such as

-

Heavy Equipment

-

Automotive & Transportation

-

Material Handling

-

Specialty Vehicle

-

Rail

-

Locomotive

-

Construction Machinery

-

Industrial Manufacturing

-

Recreational Vehicles

-

Agricultural Equipment

-

Transportation

-

Data Center

05

The Sintel Advantage

-

40+ Years of Industry Experience

-

100% Project Lifecycle Management

-

Integrated Fabrication and Finishing

-

Best-in-Class On-Time Delivery

-

10+ Engineering staff and Owner Support

06

Frequently Asked Questions (FAQs)

We implement precise cutting, welding, forming, bending, drilling, and finishing technologies personalized to your project’s specific needs.

Yes, we offer full design-for-manufacturability support, including in-house engineering, to develop parts from your concepts.

Our projects undergo rigorous quality control, inspection, and testing, aligned with industry standards and customer requirements.

Turnaround varies by project size. We collaborate closely with our customers to meet delivery schedules and have a proven track record of on-time delivery with Class A finishes.