.png)

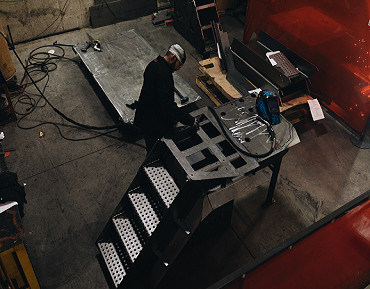

Carbon Steel Fabrication Service Built on Quality and Expertise

Your partner for reliable, high-quality carbon steel components crafted to support complex industrial needs.

01

Engineered Strength and Versatile Solutions for Industrial Needs

Improve your products and processes with high-quality carbon steel fabrication from Sintel. Our experienced team transforms sheet metal into reliable parts and assemblies crafted for demanding industrial settings. From concept through final inspection, Sintel delivers consistent quality and strong performance.

02

Why Choose Sintel for Carbon Steel Fabrication?

01

End-to-End Expertise

From initial design through final delivery, Sintel’s engineers work closely with you to optimize designs for manufacturing and ensure your parts meet exact requirements.

02

Material Knowledge

We specialize in working with carbon steel varieties that offer excellent strength and weldability, selecting the right grade for your application’s performance and cost needs.

03

Advanced Fabrication Techniques

Our skilled team utilizes precise cutting, forming, welding, and finishing processes, supported by certified welders and rigorous quality control checks.

04

Industry Adaptation

We tailor our fabrication processes to meet the specific needs of industries such as agriculture, heavy equipment, construction, energy, and manufacturing.

05

Quality Assurance

Each part undergoes thorough inspection to guarantee durability, reliability, and compliance with safety standards.

06

Collaborative Partnership

Whether starting from client drawings or engineering new concepts, Sintel supports your goals with flexible and transparent workflows.

03

Our Carbon Steel Fabrication Capabilities

Advanced Laser Cutting

Accurate shaping of parts ensures consistent fit and function in every piece.

High-Tech Press Brake Forming and Robotic Panel Bending

Shaping carbon steel sheets into multiple designs with reliability and repeatability.

Versatile Welding Solutions

Skilled manual and robotic welding techniques to achieve durable, high-integrity welds for various applications.

Comprehensive Assembly and Spot Welding

Efficiently joining subcomponents and final products with quality to support ready-to-install assemblies.

Protective Finishing Services

Expert powder coating and wet paint applications that enhance corrosion resistance and extend the life of fabricated steel.

Prototype to Production Scalability

Flexible manufacturing setup that supports quick prototyping and smooth transition to volume production, maintaining quality at every stage.

Quality Verification

Conducted detailed inspections and testing protocols throughout fabrication to ensure compliance with stringent industry standards and client specifications.

04

Industries We Serve

Our services support manufacturers across industries such as

-

Heavy Equipment

-

Automotive & Transportation

-

Material Handling

-

Specialty Vehicle

-

Construction Machinery

-

Industrial Manufacturing

-

Recreational Vehicles

-

Agricultural Equipment

-

Transportation

-

Data Center

06

Frequently Asked Questions (FAQs)

We work with various carbon steel grades, selecting the right combination of strength, cost-effectiveness, and environmental durability customized to your specific application requirements.

Yes, our in-house engineers provide guidance on design optimization to enhance manufacturability, reduce costs, and maintain quality. We also have full data, metallurgical reports, and tracking capability of your carbon steel.

Our services include laser cutting, forming, manual and robotic welding, assembly, finishing, and powder coating processes.

We conduct meticulous inspections using advanced quality lab equipment and employ certified welders to maintain strict quality standards.

05

The Sintel Advantage

-

Maximize Automation for Metal Fabrication

-

40+ Years of Industry Experience

-

100% Project Lifecycle Management

-

Integrated Fabrication and Finishing

-

Best-in-Class On-Time Delivery

-

10+ Engineering staff and Owner Support